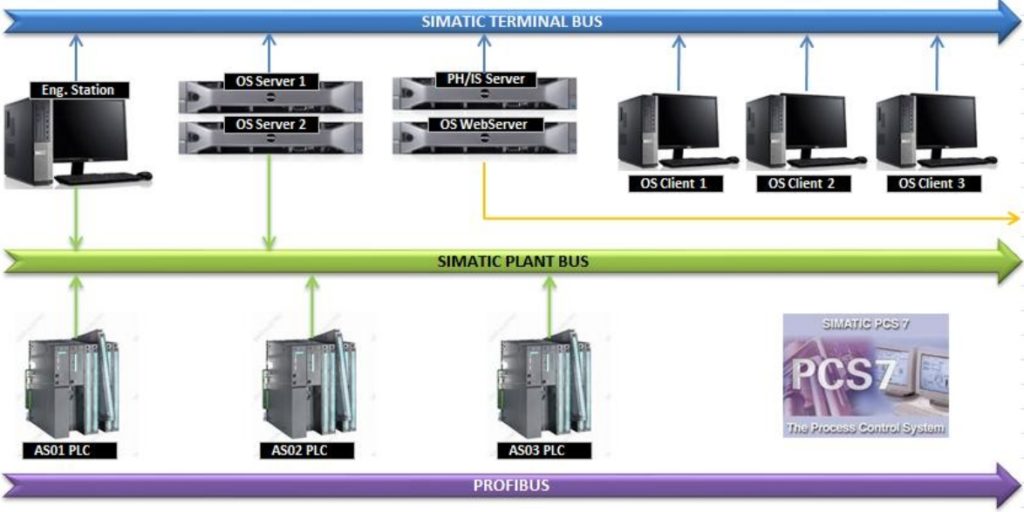

Is a Copper mine based in the south Spain that was re-furbished and installed with a new control system and new Motor control centres’. Our software engineers were sub-contracted in 2014 to provide Siemens PCS7 ver8.0 SP2 engineering services from the design phase up to the commissioning phase which was implemented in three (3) construction phases. The system comprised of the various stations as per the system architecture below and consisted of 3500 remote I/Os, 800 devices (VSDs and simocodes), various vendor system interfaces and interfaces to external controllers on profibus. ABB Protection relays installed in the medium voltage cabinets (Incomers, Transformers and Lineas) were used to control and monitor these cabinets from the PCS7 system via anybus modbus convertors. Phase 1 and 2 of the project was successfully completed in 2016 over a period of two (2) years. Phase 3 is planned for completion in June 2016. In 2018 we secured the 15M expansion project which was completed in 2019.

System Architecture:

Scope of Engineering Services:

- Installation and configuration of all AS and OS stations.

- Build of granular type multi-project environment.

- PLC and Scada software as defined by the Process functional specifications.

- Assisted with profibus network faults/failures.

- Assisted with Siemens G120/G130 VSD parameterization.

- Assisted with Simocode Pro v setup and configurations.

- Commissioning assistance and fault analysis of main plant software and hardware.

- Assisted the various vendors’ with commissioning and software changes.

- Assisted with MCC testing.

- Provide remote system support services.

- Fiber Optic Cabling, Fusion Splicing, and OTDR Testing