Leader in process and Automation Technologies

Enviroblue (Pty) Ltd is a Systems Integration company based in Johannesburg, South Africa

Service Offerings

Siemens PCS7

To date, we have successfully completed over 20 large PCS7 projects from version 4.x onwards and over 12 PCS7 migrations. Our software is based on Siemens standard APL blocks and icons as well the advanced addon packages for Simocodes, VSDs and PAC3200 power meters. We have also developed custom blocks and icons for various profibus interfaces over the past 20 years. We have assisted on clients with complete PCS7 solutions, from design to commissioning and remote support.

Siemens S7 PLCs

To date, we have assisted various clients in many different types of applications using the full Siemens S7 PLC range from design, development, interfacing to commissioning. Over the past 20 years, we have developed our own software standards that can be used on request and we also implemented custom standards as per our client’s specifications. Our software can be based on using STL, LAD, FBD, and CFC programming languages. For sequences, we have very much experience using SFC and Graph.

Human Machine Interfaces

We have assisted various clients in many different types of applications using Siemens HMIs from design to commissioning. Our competence covers the full range of HMIs offered by Siemens. We have also assisted our clients with HMI migrations. To date, we worked on the various configuration software packages namely: Protool, WinCC Flex and TIA portal.

Profibus Communication Systems

We have assisted our clients on numerous projects with profibus design, installation and testing. We are internationally certified by the PCC as Profibus Engineers and have also preformed profibus audits and assisted with fault finding.

Control Panels

We have built a multitude of various different types of panels ranging from PLC cabinets, Remote IO panels to Standalone vendor control panels. We have assisted our clients with design, manufacture, testing and commissioning of their panels. Our drawings are done using EPLAN which can be converted to ACAD if required.

Simocode Pro Series

We have assisted various clients with the design, configuration and commissioning of the various Siemens Simocodes types. Our experience includes the mapping of data to and from the PLC. We have also implemented over 500 simocodes using PCS7 and the PCS7 advance add-on packages.

Sinamic and Micromaster VSDs

We have assisted various clients in many different types of applications using Siemens Sinamics from design to commissioning. We have also assisted our clients with VSD parameterization and FATs as part of a project. To date, we have parameterized and commissioned over 200 drives, this includes Micromaster 440/420 VSD types. Our experience includes the mapping of data to and from the PLC.

MCC Testing

To date, we have assisted our clients with the factory acceptance testing and commissioning of over 100 motor control centers. This included profibus audits and rectification of communication problems. We have also assisted with the configuration and parameterization of devices such as VSDs, Simocodes, Soft Starters, Power meters, Protocol convertors and Protection relays.

Stackers And Reclaimers Commissioning

We have successfully commissioned 6 Stackers and 3 Reclaimer. The control system consisted of S7400 PLC`s as the control system and Archestra SCADA. Other installations were both Siemens PLCs and HMIs.

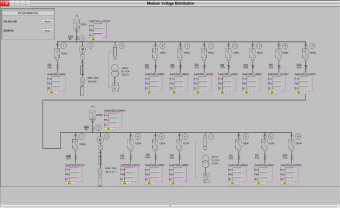

Medium Voltage Switchgear Interfaces

Our implementations involved the control and monitoring of Schneider and ABB protection relays of the main power supply cabinets. The Siemens PCS7 system was configured and programmed to interface to these relays via profibus/modus convertors.

Data structures were used to develop CFC blocks for multi-instance purposes and connected to standard APL blocks and icons for display on Scada. To enhance the integration for future expansion, process tag types were developed which also allowed for easy implementation and standardization.

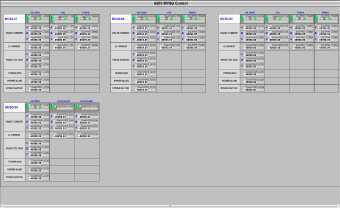

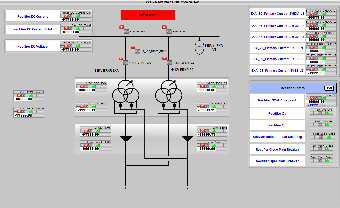

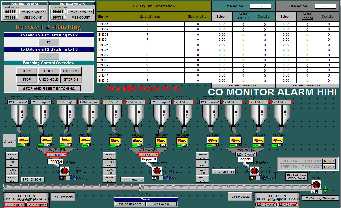

Main Power Monitoring

We have implemented various power monitoring systems on various different sites in South Africa, Africa and Europe, this includes two (2) major power management systems. Recently (featured), the monitoring systems was implemented across three (3) S7400 PLCs via profibus to PAC3200 meters. The software development is based on Siemens standard APL blocks together with the PAC3200 add-on package blocks and icons with enhanced features.

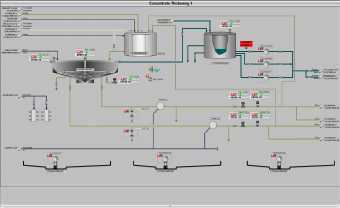

Thickener Controls and interfacing

Over the last six (6) years, we have assisted various clients with the software design, development and commissioning of approx. twelve (12) various types and sizes of Thickeners.

We have also assist with the interfacing of eight (8) Thickeners via profibus to the main plant PCS7 system. This involved configuring communications between S7400 PLCs and S7300 PLCs. Software development was done using Siemens standard APL blocks and icons for the main system and customized blocks for the vendor packages.

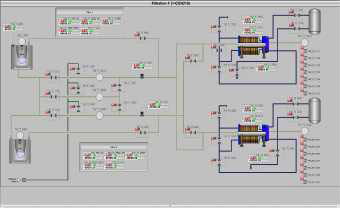

Filtration Systems

We primarily focus on the interfacing to filtration circuits for purposes of monitoring onto the main plant Scada and the interlocking of upstream/downstream equipment. We have assisted our clients with the software interface design, development and commissioning of these systems. This was achieved by configuring communications between the S7400 PLCs and S7300 / S71200 PLCs via profibus. The software development is based on Siemens standard APL blocks and icons together with customized blocks.

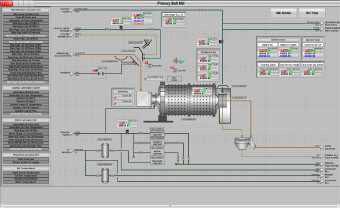

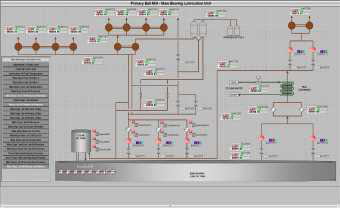

Mill Interfaces (Ball, ROD, Regrinding. SAG)

To date, we have assisted our clients with the software design, development and commissioning of 15 Mill interfaces via profibus Master/Slave communication protocol. This was achieved by configuring communications between Siemens S7400 PLCs and S7300 PLCs. Recently (featured), we implemented 2 Outotec Primary/Secondary Ball Mill interfaces in Europe with condition monitoring and custom alarming displayed on the PCS7 Scada system, this included the various lubrication systems and temperature monitoring system

ABB Rectifiers Interfacing

We have successfully interfaced to ABB rectifiers via Anybus converter (Modbus to Profibus) as part of EW section of a project in the DRC. Rectifiers could be monitored and controlled from main plant SCADA using PCS7 V8 .0 SP1.

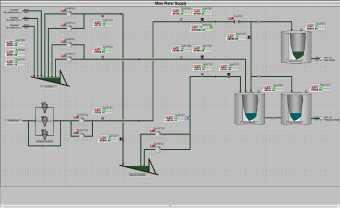

Water Management Systems

To date, we assisted various clients on six (6) different mines with the software design, development and commissioning of water supply, treatment and management systems. This involved the interfacing to various different external controllers and vendor packages via profibus. We have also designed and developed reports using Siemens Process Historian to query relevant process data and the display of real-time / historical trends as part of the PCS7 control system. Our software was based on Siemens standard APL blocks and icons.

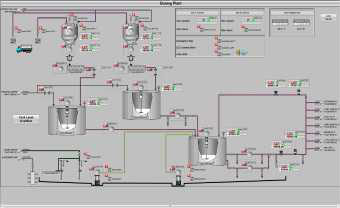

Flotation and Cleaner Systems

Over the last two (2) years, we assisted our clients with the software design, development and commissioning of flotation circuits on two (2) different copper mines.

Our software was developed using Siemens PCS7 standards for the control and monitoring of the process. We have also successfully “loop tuned” PID level controllers for optimum efficiencies.

Lubrication Systems

We have assisted various clients with the software design, development and commissioning of various different lubrications systems over the past 15 years using Siemens PLC controllers as well as Siemens PCS7 systems with conditioning monitoring and custom alarming. Depending on the application, some systems were based on custom software design and development whilst Siemens standard APL blocks and icons were used for other systems.

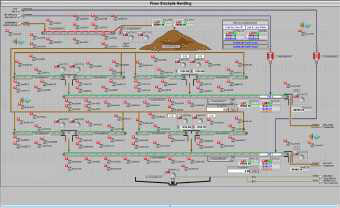

Material Handling Systems (Crushing, Screening, Weigh Feeders, Vibration Feeders, Conveyor Systems)

To date, we have implemented numerous material handling systems for various clients both locally and internationally. We were involved in the software design, development and commissioning phases of eight (8) major projects. This also entailed the interfacing to external feed controllers and weightometers via profibus to the PCS7 system. Our software was developed using Siemens standard APL blocks, SFCs and icons for control and monitoring of the various material components.

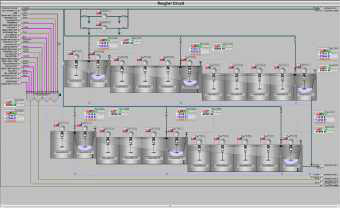

Reagent Systems (Lime, Flocculant, Collectors, Frother Systems)

Having implemented over 56 different types of dosing plants for various industries, we have gain much experience and knowledge over the past 20 years assisting our clients with software design, development and commissioning of these processes. Some of our software designs also involved profibus interfacing to these systems and the main PCS7 system using Siemens S7400 PLCs and vendor supplied S7300 / S71200 PLCs.

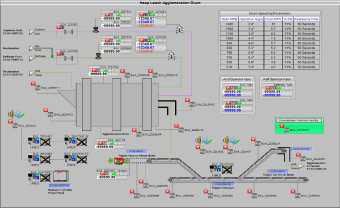

Heap Leach / Agglomeration

Over the last three (3) years, we assisted our clients with the software design, development and commissioning of agglomeration circuits on two (2) different copper mines. Our software was developed using Siemens PCS7 standards for the control and monitoring of the process. We have also successfully “loop tuned” PID flow controllers for optimum efficiencies.

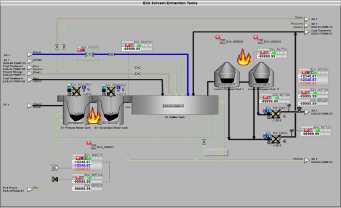

Furnaces and Sintering Plants

We have assisted our clients with upgrading of custom batching systems using standard PCS7 blocks, SFC`s and icons, this included critical alarming and interlock traceability via the Scada system.

SX

In 2013, we assisted our clients with the software design, development and commissioning of Solvent Extraction circuit on a copper mine in the DRC. Our software was developed using Siemens PCS7 standards for the control and monitoring of the process.

Process Automation

Our solutions and services include the installation, configuration, programming and commissioning of the AS/OS stations, Webserver, Process Historian, industrial ethernet and profibus networks.

Fibre Optics

From cable placement to splicing and testing. Enviroblue will put you on your way to complete fibre optic network services at the best quality and affordable rates.

Power

We provide custom solar, inverter and UPS solutions to provide you with continuous energy cost-effective.

Panel Building

We design and manufacture panels to your desired specification. Panel solutions may include PLC cabinets, remote IO stations, DB panels and more.

Support Services

We will ensure the support of installation and commissioning services, fault finding and remote system support wherever you may be located.